NEWS powered by

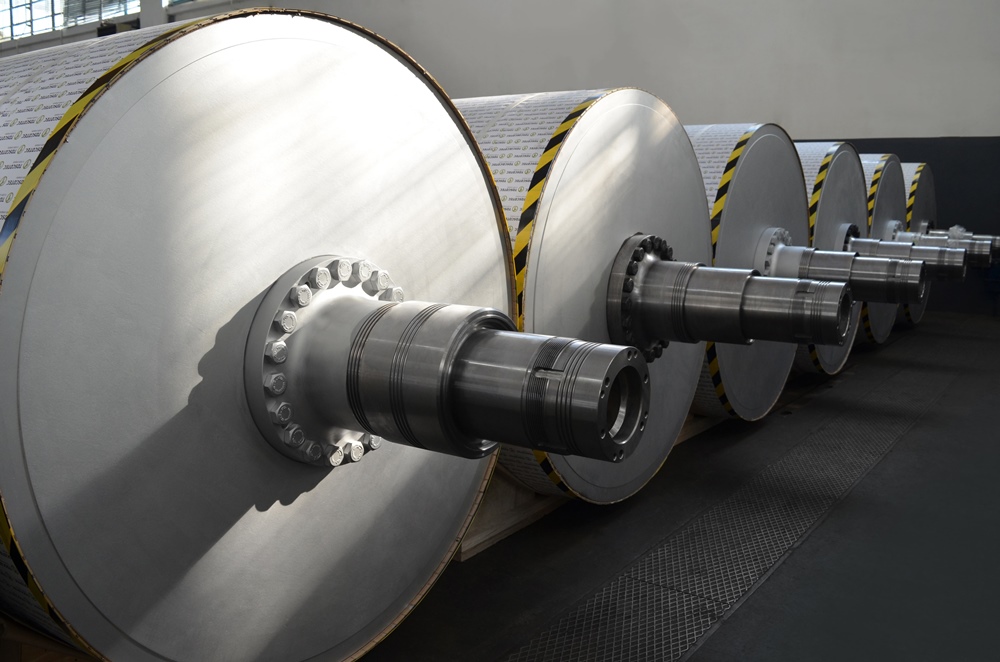

Voith to make multi-million-dollar investment in West Monroe roll service center

Voith is modernizing and expanding its roll service center in West Monroe, La., underscoring its firm commitment to the future of the paper industry and the evolving needs of customers. The expansion will be Voith Paper’s largest, most recent investment in North America.

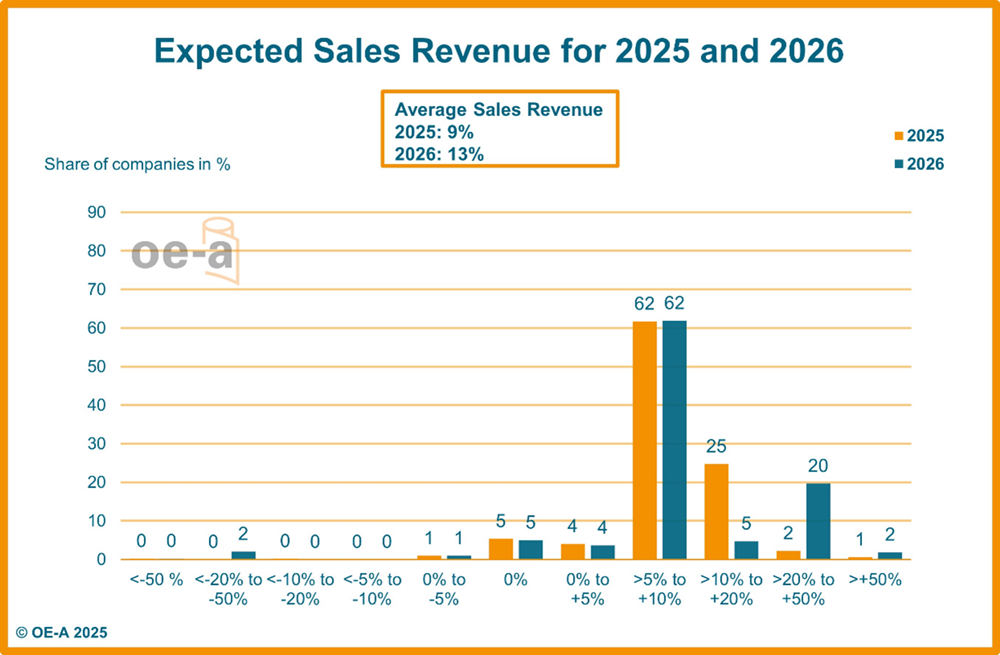

OE-A Business Climate Survey 2025: Cautious growth and strategic investments in printed electronics

“While flexible and printed electronics companies are approaching 2025 with caution, there is evident confidence in long-term growth, particularly in key end-user industries such as consumer electronics, automotive and healthcare,” said Dr. Alain Schumacher, OE-A Chairman and CTO of IEE in Luxembourg, commenting on the results of the OE-A Business Climate Survey at the LOPEC Press conference on 26 February in Munich. The outlook for the flexible, organic and printed electronics industry has weakened compared to previous surveys.

Andritz airlay line for nonwovens production from recycled glass wool starts up at Revibat, France

International technology group Andritz supplied and recently commissioned a state-of-the-art neXline airlay system for Revibat, France. This innovative line, inaugurated at the beginning of February, enables the production of building insulation panels from glass wool waste that would otherwise be sent to landfills. With the new Andritz line, Revibat can now transform complex waste collected in the Paris region into valuable products. The patented process addresses two major challenges: giving a second life to insulation glass wool waste and reducing the carbon footprint across the entire production chain.

Klopman commits to 100% renewable energy and further reduces emissions with new innovations

Klopman, a global player in the production of high-performance fabrics for workwear, protectivewear, and casual apparel, is proud to announce a major milestone in its commitment to sustainability. From today, 100% of the energy used in all Klopman production processes will be derived exclusively from hydroelectric sources. The company is carrying out LCA – Lyfecycle Assessments on all its fabrics and the introduction of this major implementation will bring a benefit between 6 and 8% in the products Carbon Footprint (depending on the fabric).

Hunkeler Innovationdays

From the white roll to the finished book

At the Hunkeler Innovationdays taking place in Lucerne, Müller Martini and Hunkeler will showcase a complex all-in-one system for softcover products from the printing press to the trimming robot with a downstream sorting line following the motto, “From the white roll to the finished book.” With the production of eight different books in the 3-up-rolls and 2-up-rolls process, the automated switching of book formats and cut-off lengths will be demonstrated live.

Packaging is the new brand statement

Mondi announced the results of its sixth annual eCommerce trend report “Sustainability and its impact on packaging and online shopping choices”. This comprehensive study examines trends, attitudes and expectations regarding eCommerce and the impact packaging has on the consumer experience. The report presents data from around 6,000 consumers across Czechia, France, Germany, Poland, Sweden and Türkiye, collected via an online survey in October and November 2024. The findings offer eCommerce brands valuable insights on meeting consumer needs, including country-specific results from each of the six markets. The survey was conducted by RetailX, who also co-authored the whitepaper.

BW Converting introduces the Winkler+Dünnebier (W+D) BB816+ mail inserter at HID

Under its Winkler+Dünnebier (W+D) brand, BW Converting announces the launch of the BB816+ high-performance mail inserter. This new addition to the 800 series platform of servo-driven, easier-to-operate mail inserters is built for direct mail, transactional mail and specialized applications such as vote by mail, offering the highest levels of integrity and adaptability for customized solutions.

Hunkeler Innovationdays

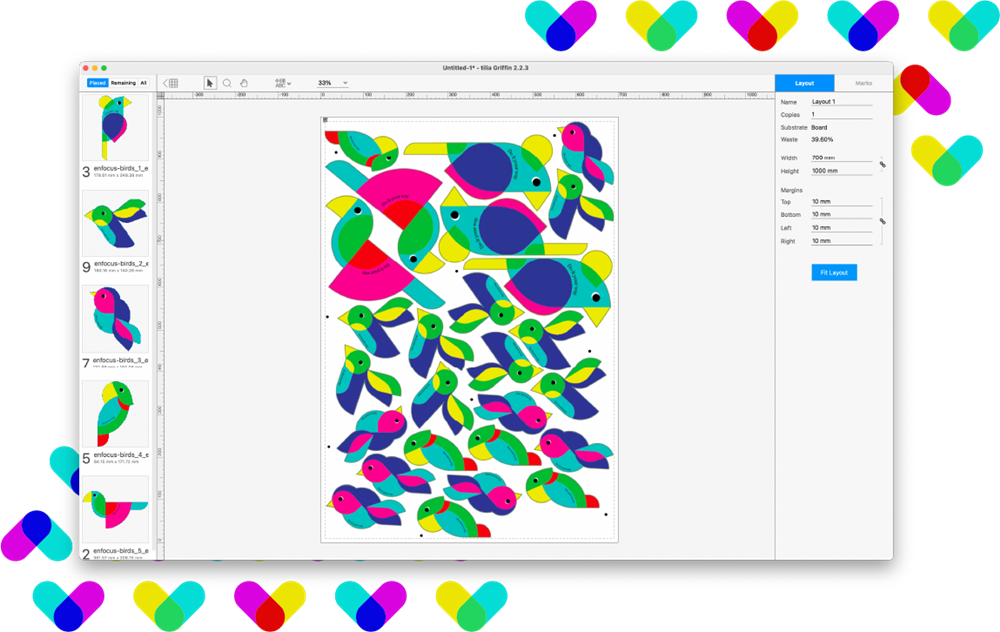

Enfocus brings latest automation innovations to Hunkeler Innovation days

Automation expert Enfocus is taking its print software solutions on the road once again as it returns to the Hunkeler Innovationdays event in Lucerne, Switzerland.When the biennial event returns to Messe Luzern on February 24-27, attendees who visit the Enfocus booth will have the chance to experience the power of Enfocus solutions – widely regarded as the gold standard of prepress software – for themselves. These solutions include the latest versions of PitStop, Switch, Griffin, Review, and Phoenix, all of which were updated at the end of 2024 with a host of new features, functionality, and integrations to boost productivity and profitability across the print workflow.

Valmet to retrofit automation at KSS Energia’s Verla 2 hydropower plant in Finland

Valmet will modernize the automation system at KSS Energia’s Verla 2 hydropower plant in Kouvola, Finland. The Valmet DNA Hydro Turbine Automation will replace an obsolete third-party system on the site. The new automation system plays a crucial role in improving the operational reliability of the hydropower plant. The order was included in Valmet’s orders received of the fourth quarter 2024. The value of the order will not be disclosed. The delivery will be taken over by the customer in December 2025.

“The two new machines are increasing our production reliability”

In order to increase automation in both saddle stitching and perfect binding, Silber Druck, based in Lohfelden in the German state of Hesse, has invested in two new finishing systems from Muller Martini – a Primera Pro and an Alegro.

Toscotec continues penetration of US market with new TT SteelDryer start-up

Toscotec has recently completed a dryer section rebuild including more than 10 TT SteelDryer cylinders at an American paper producer that remains confidential. This group has placed numerous repeat orders relating to four different production bases in the USA. In North America, Toscotec has installed more than 70 TT SteelDryers to date.

Hunkeler Innovationdays

Solimar Systems joins key partners at Hunkeler Innovationdays

Solimar Systems, Inc., provider of workflow software solutions for print production and digital communications, announces their participation and support at Hunkeler Innovationdays (HID) in key partner stands: RISO and Screen. Solimar staff will demonstrate the benefits and use cases of their industrial PDF optimization solution: ReadyPDF® Prepress Server. This product optimizes fonts, images, objects, and colors and fixes most structural issues, creating PDFs that process more efficiently for printing on production cut-sheet devices, continuous feed presses, and for online ePresentment, with full document fidelity.