NEWS powered by

ZELLCHEMING

ZELLCHEMING Expo 2025: Two good reasons to celebrate

In 2025, ZELLCHEMING - the Association of Pulp and Paper Chemists and Engineers - looks back on 120 years of association history. At the same time the ZELLCHEMING-Expo celebrates its 75th anniversary. The two anniversaries have been combined - to celebrate 195 years in style!

Toscotec publishes Sustainability Report 2024

Toscotec is pleased to announce the publication of its first Sustainability Report as the latest integration of its long-standing commitment to sustainability, which dates back to 2005 with the award of its first environmental certification. The issuance of a Sustainability Report in accordance with the GRI standards (Global Reporting Initiative) comes as a strong signal of continuity on the company’s journey of contributing to a more sustainable future for the paper industry.

FEFCO launches the 1st Edition of the FEFCO Cybersecurity Handbook

The European Federation of Corrugated Board Manufacturers (FEFCO) is proud to announce the release of the first edition of the FEFCO cybersecurity handbook and associated tools. This initiative represents a major step forward in enhancing the cybersecurity resilience of the corrugated industry while preparing for the upcoming European regulations.

Valmet to supply two winders to Wuzhou Special Paper in China

Valmet is to supply two OptiWin Drum two-drum base winders to Wuzhou Special Paper’s paper machine PM 21 in China. This new order follows the customer’s previous winder order, announced in July 2024. The target of this latest investment is to have high-technology winders that can meet the paper machine’s high capacity and quality objectives. The order is included in Valmet's orders received of the first quarter 2025. The value of the order will not be disclosed.

Voith launches dynamic ecosystem MillOne

As a pioneer in the field of autonomous paper mills, Voith has already been able to position itself strongly in recent years and has set the course for a digitalized and connected future of paper production. Now, with the launch of its ecosystem MillOne, the full-line supplier is taking the next important step on the way to a completely autonomous paper mill. The new platform combines all relevant systems, optimizes processes in real time, and enables the intelligent connection of all production steps. With MillOne, Voith creates the basis for a more efficient, more sustainable, and more economical paper production – and takes another big step towards its future-oriented vision of the autonomous paper mill.

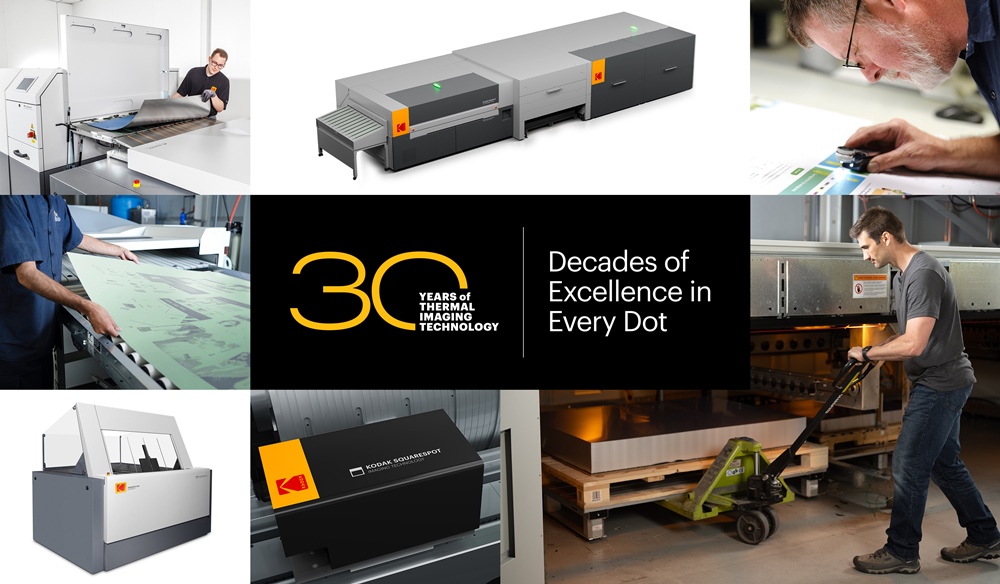

Kodak celebrates 30th anniversary of thermal plate imaging

This year, Kodak proudly celebrates the 30th anniversary of a technology innovation that revolutionized prepress and on press processes. Kodak manufactured and first introduced thermal plate imaging at drupa 1995, and Creo (acquired by Kodak in 2005) developed the first thermal platesetter. This spectacular unveiling of disruptive technology was the starting point for the fundamental transformation of the CTP market towards thermal imaging.

Andritz launches R&D program to double value from wood without more harvesting

Andritz is launching a comprehensive research and development program called BioCircleToZero, which aims to double the value derived from wood without harvesting more trees. Business Finland, the government’s agency for trade and investment promotion, has granted Andritz 10 million euros in funding for the BioCircleToZero program. An additional 20 million euros will be provided by Business Finland to partners contributing to the program.

Valmet delivers complete IQ Quality Management System package to pressure-sensitive laminate producer in North America

Valmet has received an order for a complete Valmet IQ Quality Management System package from one of North America’s largest pressure-sensitive laminate producers. It will be delivered to the customer’s Midwest facility and include Valmet IQ Moisturizers for moisture and curl control, Valmet IQ Silicone measurement, Valmet IQ Reflective Spectrometer measurement for adhesive, two Valmet IQ Single Sided Scanner S units, and closed-loop moisture MD/CD control and MD Silicone control. The order is included in Valmet’s orders received for the first quarter of 2025. The value of the order will not be disclosed. The delivery is scheduled for August 2025.

EraCup Natural by Lecta obtains DIN CERTCO industrial compostability certification

Lecta has achieved DIN CERTCO industrial compostability certification for its EraCup Natural paperboard, an innovative product for food service applications. Why is this certification important? It ensures that compostability claims are scientifically validated and that items are accepted in industrial composting facilities, unlike “biodegradable” products that may not fully degrade.

Drytac Polar Frost Air: Sophisticated frosted look

Drytac, international manufacturer of self-adhesive materials for the large-format print and signage markets, is delighted to announce the global launch of Polar Frost Air, a new translucent matte polymeric PVC film with an embossed pearl finish that becomes the latest addition to the Polar product range. Suitable for use in both indoor and outdoor applications, Polar Frost Air features a subtle embossed finish that replicates the elegant look of etched glass but at a more affordable price point.

Lecta presents barrier base paper Linerset FP

As part of its strategy to provide high-value, innovative, and environmentally responsible products, Lecta introduces Linerset FP, a high-performance barrier base paper designed for flexible packaging solutions. This product is the ideal solution for converters and printers seeking to incorporate advanced barrier properties into their packaging, or using it as it is, offering a strong, flexible, translucent alternative for use in bags, pouches, and wrapping applications.

Kodak: Full-scale commercialization of new Sonora Ultra Process Free Plates in Europe

Kodak is excited to announce it will upgrade its Sonora XTRA-3 customers in Europe to the latest innovation in the Sonora line, Kodak Sonora Ultra Process Free Plates.