NEWS powered by

Sappi Europe announces a price increase for Coated and Uncoated Fine papers

Due to rising input costs, particularly but not only for pulp, Sappi Europe intend to increase prices for Coated and Uncoated Fine Papers by 8% effective from 7 April 2025. Sales teams will be in contact with our customers to discuss implementation details.

Simatic Robot Pick AI Pro enables machine builders to develop their own adaptive picking robots

Siemens is presenting its new developments in industrial automation and digitalization for the intralogistics industry at this year's Logimat. Faced with global challenges like labor shortages, growing sustainability requirements, and demographic change, the technology company is introducing innovative automation and digitalization solutions that increase efficiency, adaptability, and sustainability in intralogistics.

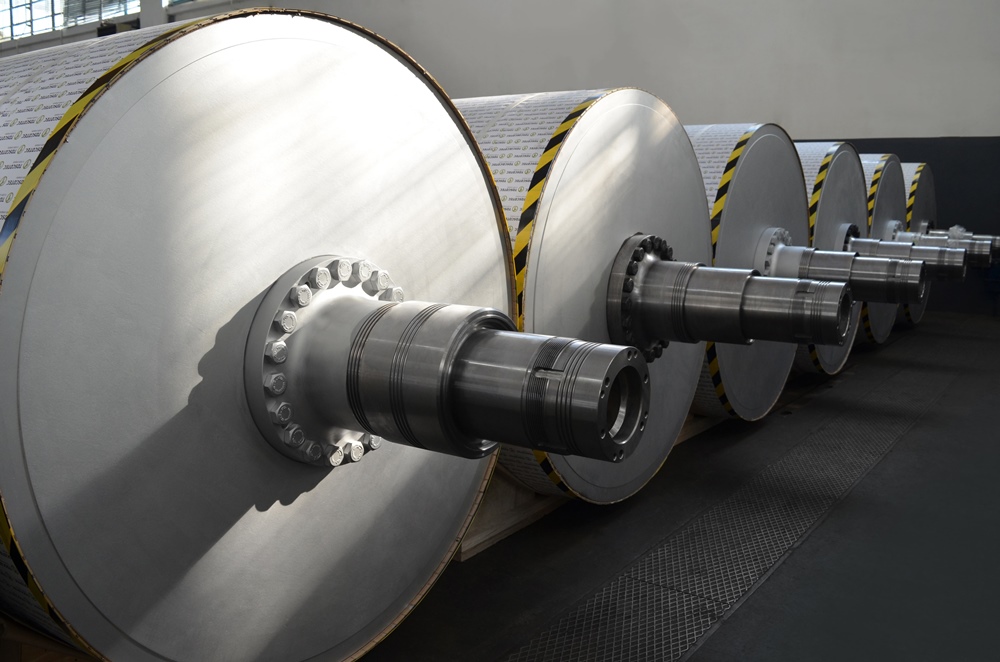

Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

Valmet is to supply an OptiWin Drum two-drum base winder to Jingxing Holdings’ board machine PM 3 in Malaysia. The target of the investment is to have high-capacity winding technology that meets the requirements of the board machine. The start-up of the winder is scheduled for 2026. The order is included in Valmet's orders received of the first quarter 2025. The value of the order will not be disclosed.

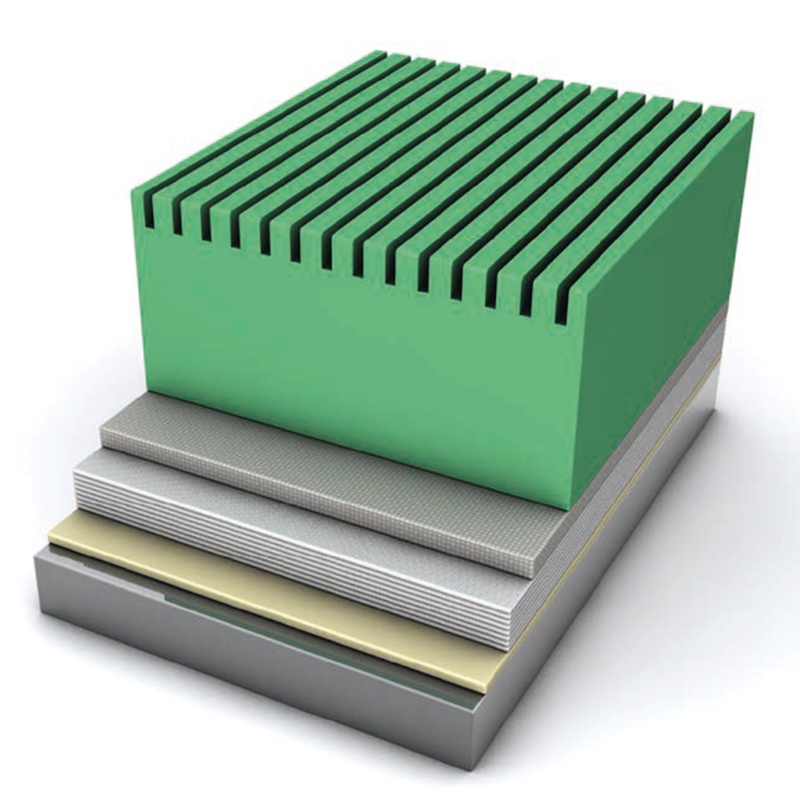

SolarPress Green sets new standards for bio-based roll covers

The sustainable roll cover family keeps growing: SolarPress Green, together with SolarFlow Green and AiroGuide Tune Green, expands the portfolio with another sustainable solution and sets new standards in the paper industry. With SolarPress Green, Voith offers another bio-based polyurethane press roll cover with a hardness range of 5 to 20 PJ – while providing the same mechanical performance as the proven SolarPress roll cover.

Emtec Electronic to exhibit with IDMtest at SPAPER 2025 in Zaragoza

The German company emtec Electronic GmbH will participating with its partner IDMtest as an exhibitor at SPAPER 2025, which is set to take place from March 4–6, 2025, at Feria de Zaragoza, Spain. The shown laboratory devices, used in the wet-end area and for base and final paper products, are said to focus on efficiency, precision, and sustainability, helping to optimize production processes.

Mondi’s re/cycle SpoutedPouch replaces plastic tubs for paint

Mondi collaborated with Sherwin-Williams, a global company in paints and coatings, to introduce re/cycle SpoutedPouch as a refill option for its concentrated paint, sold on the UK market. Leveraging the expertise in its Halle/Steinfeld plant in Germany, Mondi introduced a wider spout for easier filling and pouring, while ensuring the mono-material pouch is designed to protect its contents.

Voith to make multi-million-dollar investment in West Monroe roll service center

Voith is modernizing and expanding its roll service center in West Monroe, La., underscoring its firm commitment to the future of the paper industry and the evolving needs of customers. The expansion will be Voith Paper’s largest, most recent investment in North America.

Packaging is the new brand statement

Mondi announced the results of its sixth annual eCommerce trend report “Sustainability and its impact on packaging and online shopping choices”. This comprehensive study examines trends, attitudes and expectations regarding eCommerce and the impact packaging has on the consumer experience. The report presents data from around 6,000 consumers across Czechia, France, Germany, Poland, Sweden and Türkiye, collected via an online survey in October and November 2024. The findings offer eCommerce brands valuable insights on meeting consumer needs, including country-specific results from each of the six markets. The survey was conducted by RetailX, who also co-authored the whitepaper.

Toscotec continues penetration of US market with new TT SteelDryer start-up

Toscotec has recently completed a dryer section rebuild including more than 10 TT SteelDryer cylinders at an American paper producer that remains confidential. This group has placed numerous repeat orders relating to four different production bases in the USA. In North America, Toscotec has installed more than 70 TT SteelDryers to date.

New CleanLine Extract360 fabric cleaning system from Voith maximizes dryer section cleanliness

With the CleanLine Extract360, full-line supplier Voith is launching a new, highly effective fabric cleaning system for the dryer section of paper machines. The innovative system is designed to overcome limitations of conventional dryer fabric cleaning, enabling excellent cleaning results, reliably removing wastewater, and extending fabric life by reducing cleaning pressure. By keeping the fabric, the cleaning system itself and the entire dryer section cleaner, the technology makes a significant contribution to the runability of the machine and reduces the risk of paper defects.

Suzano reaches nominal capacity and 1 million tons of production in record time with Andritz-delivered pulp mill

Suzano has reached remarkable production milestones at its new pulp mill in Ribas do Rio Pardo, Brazil, delivered by Andritz. The world’s largest single-line eucalyptus pulp mill achieved average nominal capacity within less than six months after start-up, nearly four months ahead of schedule. Another milestone was met on January 8 when the mill’s production reached its first 1 million tons of pulp. When fully operational, the mill will have an annual production capacity of 2.55 million tons.

Hunkeler Innovationdays

Mondi: Wide range of high-speed inkjet papers at Hunkeler Innovationdays

Mondi is back at Hunkeler Innovationdays, a premier continuous feed and sheet fed technology and networking event. From 24 to 27 February, the company will be in Lucerne, Switzerland to present its comprehensive portfolio of high-speed inkjet papers.