NEWS powered by

Voith is modernizing PM 3 at Smurfit Westrock Navarra to improve MG paper quality

Voith has received the order to modernize the PM 3 paper machine at Smurfit Westrock Navarra, S.A., in Sangüesa, Spain. Enrique Sanz, Industrial Manager at Smurfit Westrock Navarra, emphasizes: “Working with Voith on this project is another important milestone in our continuous improvement of production capabilities. We are confident in Voith's expertise as a leading full-line supplier and believe that the rebuild will deliver the desired production benefits to enable our continued strategic growth and delivery for our customers.”

BW Flexible Systems unveils upgraded Hayssen R300 with OpView™ HMI

BW Flexible Systems has announced enhancements to its Hayssen R300 flow wrapper, which originally launched one year ago at Pack Expo East. Now, the solution will come standard with BW Packaging's award-winning OpView™ human-machine interface (HMI), offering significant improvements to user training and operation, as well as providing baked goods producers with the flexibility necessary to adapt their equipment with their ever-evolving production needs.

Gundlach Packaging joins European Rotogravure Association (ERA)

The European Rotogravure Association (ERA) is pleased to announce that Gundlach Packaging Group has joined as a new member. With more than 170 years of excellence in the packaging industry, Gundlach brings deep-rooted expertise and innovation to the ERA community. Headquartered in Oerlinghausen, Germany, Gundlach Packaging is a premium provider of high-quality packaging solutions, specializing in rotogravure, flexographic and Offset printing. With two state-of-the-art production facilities and a team of over 400 employees, the company delivers custom-designed flexible packaging for renowned clients in the food, non-food and tobacco industries in- and outside Europe.

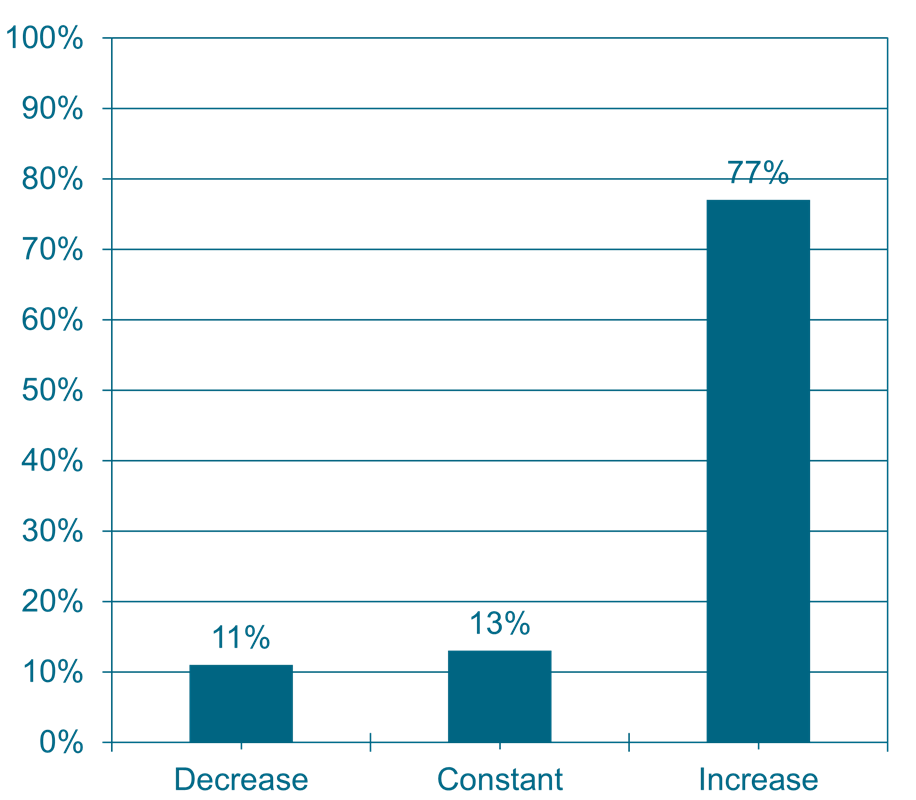

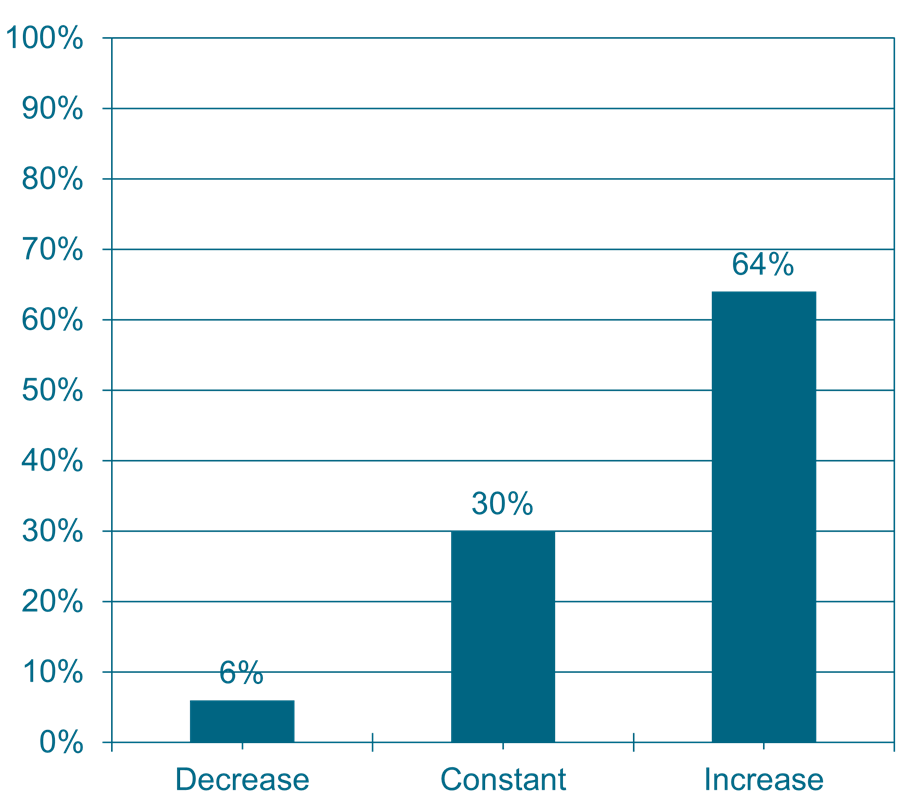

Additive manufacturing industry optimistic despite challenges

“Our member companies continue to demonstrate remarkable stability and adaptability in a changing market environment,” explains Dr. Markus Heering, Managing Director of the VDMA Additive Manufacturing Working Group. The working group's spring 2025 survey shows that the additive manufacturing industry remains optimistic despite some challenges. The survey was conducted until March 28, i.e. before the US tariffs were introduced. One result is that more companies reported positive sales than in the previous fall survey. Nevertheless, 34 percent of companies reported declining sales for the last 12 months. In the past 6 months, however, the negative turnover of member companies was only 20 percent. “We are therefore seeing a slight trend towards more positive business,” explains Dr. Heering.

SCA signs service contracts with Andritz for pulp mill in Sweden

International technology group Andritz has been awarded significant service contracts by SCA, Europe’s largest private forest owner, to further improve the performance of the Östrand pulp mill in northern Sweden. The contracts include the replacement of an economizer in the recovery boiler and the implementation of the Synergy Services concept for the white liquor plant and pulp drying processes. These improvements will increase availability and efficiency, thus helping to deliver the mill’s primary objective of increasing pulp production.

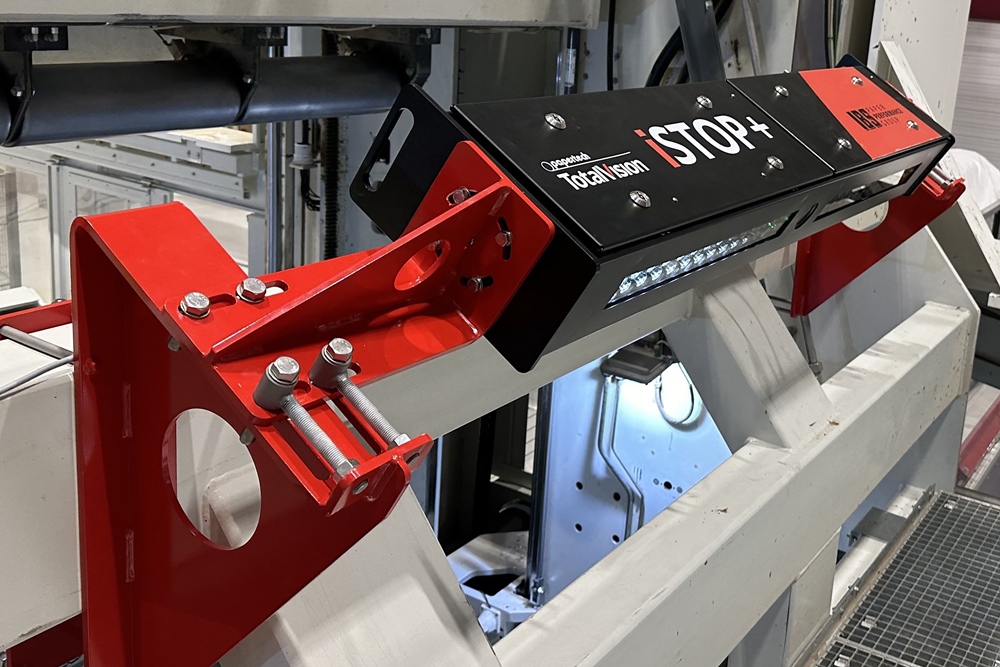

Efficiency significantly increased on the PM3 winder from Progroup Sandersdorf

IBS Papertech, a member of the IBS Paper Performance Group, has achieved another milestone with its iSTOP+™ technology. The camera-based process for increasing the efficiency of winders has been successfully in operation since 2023 on PM3 at Progroup AG in Sandersdorf-Brehna (Germany), one of the world's most modern and efficient paper mills. The winder with double unwinding is under great production pressure. With the iSTOP+, a contactless and low-maintenance solution is now available to fully meet the challenges.

Hankyung Media Group: Colorman e:line installations successfully tested

Hankyung Media Group, the publisher of the renowned The Korea Economic Daily, has reached another milestone in its comprehensive newspaper printing project with the successful test runs of its two new Colorman e:line printing presses from manroland Goss. On Monday, the new production facility impressed during a formal ceremony attended by Kim Jung-Ho, President and CEO of Hankyung Media Group, with its excellent print quality, high production speed, and advanced automation. The new printing plant sets the standard for innovation and efficiency, reinforcing Hankyung Media Group’s position in the South Korean newspaper industry.

Oppboga Bruk nominated as partner for Ensocoat 2S™

Stora Enso has started a partnership with Oppboga Bruk AB, producer of multiply paperboard for signs, displays and packaging, for the lamination and sale of Ensocoat 2S™ in 450, 500 and 600gsm. “Our Scandinavian neighbour will ensure high-quality service thanks to their proximity to our manufacturing plant and the wide range of raw paper reels they hold at their site in Fellingsbro,” says Tomas Larsson, Head of Product Line SBS, FBB, Liner & Book Paper at Stora Enso.

Creaset HGP: Lecta’s new paper for grease-proof flexible packaging

Lecta is firmly committed to delivering innovative and more sustainable products that support a circular economy. The broad range of flexible packaging papers, made from natural, recyclable, and renewable raw materials, is designed to protect product integrity with optimal barrier properties. The launch of Creaset HGP reflects this, creating packaging solutions that meet the evolving demands of today’s consumers.

World’s first fully electric tissue machine operates at full speed at Fortissue

Portuguese tissue manufacturer Fortissue and Toscotec have started up PM1 after a groundbreaking upgrade at their Viana do Castelo production base in Portugal. This Toscotec-supplied Ahead 2.0 line, which first began production in 2015, is now the first tissue machine in the world to operate entirely on electricity at 2,000 m/min.

Kien Label installs fifth MPS press

Kien Label B.V., a Dutch producer of complex multi-layer labels and part of the Asteria Group, has further strengthened its production capabilities with the addition of an MPS EFS-430 8-color flexo press. This marks the company’s fifth MPS press and reflects its continued commitment to innovation, efficiency, and sustainability in label production.

Important statement regarding event name confusion

Al Furat Group would like to share an important announcement regarding recent confusion in the industry about an event name that closely resembles their internationally recognized Paper & Tissue Show, organized by Al Furat Group in Abu Dhabi.