P3 7-8/2023 en

Voith VMax Add-On

Next Generation in Efficiency and Sustainability for Press Felt Applications

Focus On

VMax by Voith helps board and packaging manufacturers become more efficient and competitive by providing steady-state performance during its running time.

As a leader in paper production technologies, Voith closely follows the industry's global markets. In the past year, inflation has led to a decline in e-commerce and a reduced consumer demand for paper. Consequently, our customers are experiencing falling paper prices while raw materials and energy costs continue to rise. Some paper producers are opting to take production downtime to reduce supply in an effort to keep prices up.

VMax by Voith helps board and packaging manufacturers become more efficient and competitive by providing steady-state performance during its running time.

The need for innovation in board and packaging production

Nevertheless, paper manufacturers are counted on to supply the packaging needed for products to be shipped to the doorsteps of consumers around the world. Even with rising costs, board and packaging manufacturers need to maintain output while adhering to quality standards and ensuring competitive pricing. This is no simple task. As a result, papermakers are seeking next-generation manufacturing technologies to deliver improved levels of efficiency and scalability.

Innovation in press felt efficiency add-ons

The press section is a vital part of the paper machine in which new technologies have led to efficiency gains. In this area, Voith has proven itself to be an innovator by delivering solutions to meet the challenges of the paper industry. Its pioneering Vector creation – the efficiency add-on module for press felts – has been a game changer for paper producers.

First introduced in the early 2000s, Vector is a structured, functional layer within the press fabric that has been widely adopted around the globe. For many years, it has proven to be a versatile solution to extending the working window of press felts and is still, to this day, commonly used in paper machines. Now, with the growing focus on high-volume board and packaging production, Voith is supporting its customers’ efforts to be more efficient and sustainable by providing Vmax – the next-generation add-on module for press felts.

Vector to the max = VMax

Building on the success of Vector, VMax is a non-woven multi-functional substrate that extends the working window of press felts and, as an efficiency add-on, can be used in combination with Voith press felts such as Infinity, Multiflex, PrintFlex and CellFlex. The VMax technology can be utilized for many applications, including board and packaging, pulp and graphic paper production. VMax can be tailored to suit the wide array of applications found in different regions.

VMax retains permeability to ensure consistency

To achieve ongoing efficiency improvements in papermaking, optimizing the working window and consistency of the press felt is crucial. VMax has been specifically designed to keep the felt open, which reduces contamination within the felt structure. This reduction in contamination leads to improved porosity retention throughout the life of the felt. Consistent porosity makes the felt easier to clean while maintaining high uniformity throughout its lifetime. This translates into more efficient paper production.

Results have shown that VMax increases felt permeability retention by up to 20 percent, resulting in an extended working life of the press felt by up to 20 percent.

“VMax helps board and packaging manufacturers become more efficient and competitive by providing steady-state performance during its running time. By having the ability to handle large amounts of water, resist compaction and contamination, and require less chemical cleaning, VMax contributes to lower chemical costs, higher machine efficiency and higher production over its service life,” says Mike Riffle, Technical Sales ExpertPress Fabrics, Voith US.

One technology, many benefits

Voith designed VMax to directly address customer efficiency needs and, because of this, all of its unique properties translate into tangible benefits in the paper production process. Specifically, VMax has demonstrated that it resists compaction and contamination over the lifetime, thereby extending fabric life. VMax also maintains high porosity for higher steady-state uhle box dewatering and eliminates the need for repeated cleaning. These features lead to water, energy and chemical savings thanks to reduced cleaning.

“As costs rise within all industries, VMax helps our customers run the felts longer and with less energy and chemicals. The ability of VMax to dewater and stay clean yields better and more stable performance over the life of the felt and enables the customer to run a felt full life with efficiently scheduled felt changes,” states Sandra Rae, APAC Product Manager Press Felts, Voith Paper.

One small part of a bigger solution

VMax has already significantly impacted paper production processes worldwide by helping paper manufacturers increase production, control costs and improve sustainability. This is particularly good news for the expanding board and packaging industry, which is facing growing global demand for paper products.

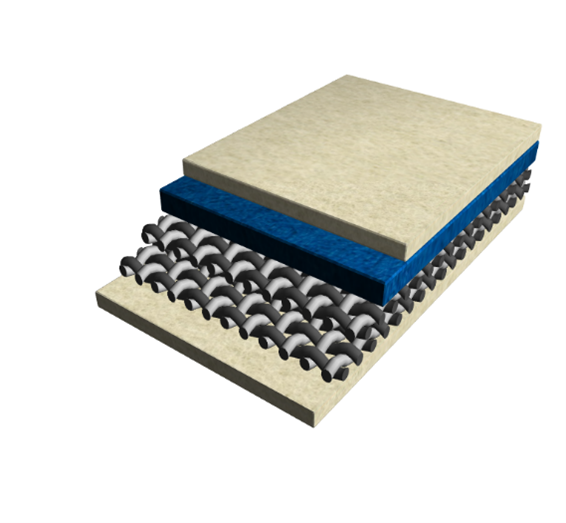

The VMax within the press felt: White represents the batt layers, blue represents the VMax layer, and grey represents the Infinity woven base layer.

Author: Anne Klaschka, Global Product Manager Press Fabrics, Voith

Editor: sbr

Images: Voith